Steel Braided Flexible Wires

Steel Braided Flexible Wires

Steel braided flexible wires, also known as braided cables or braided wire assemblies, are electrical cables that feature a flexible outer covering made of braided steel wire. These cables are commonly used in various applications where flexibility and durability are required, such as in automotive, aerospace, industrial machinery, and electronic equipment.

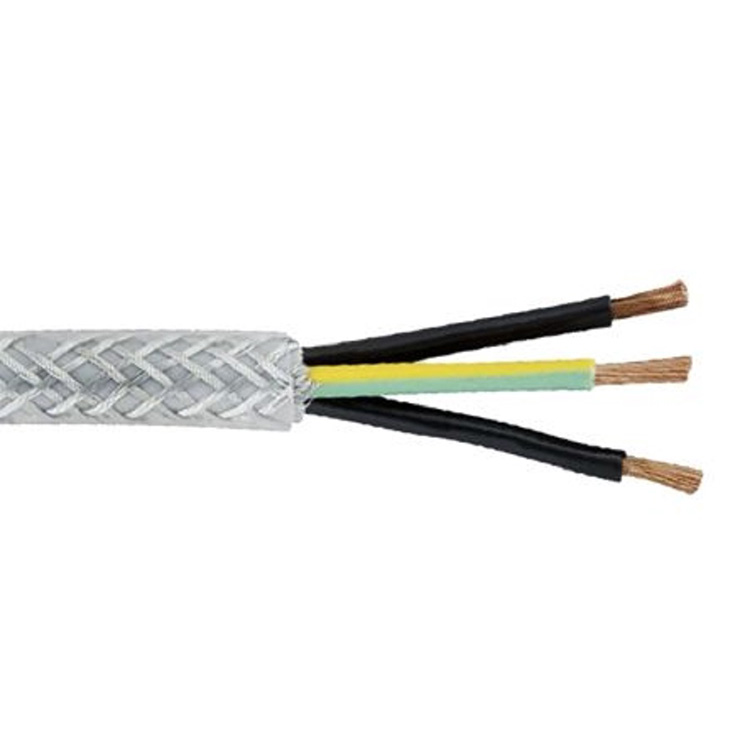

The construction of steel braided flexible wires typically involves a central conductor, such as copper or aluminum, which carries the electrical current. This conductor is surrounded by one or more layers of insulation materials, such as PVC (Polyvinyl Chloride) or PTFE (Polytetrafluoroethylene), to provide electrical insulation and protect against environmental factors.

The outermost layer of the cable consists of braided steel wire. This braiding serves multiple purposes. First, it provides mechanical protection to the underlying layers, enhancing the cable’s durability and resistance to wear and tear. Second, the steel braiding offers excellent flexibility, allowing the cable to bend and twist without compromising its electrical integrity. The braided design also helps in reducing electromagnetic interference (EMI) and radio frequency interference (RFI) by acting as a shield against external electromagnetic signals.

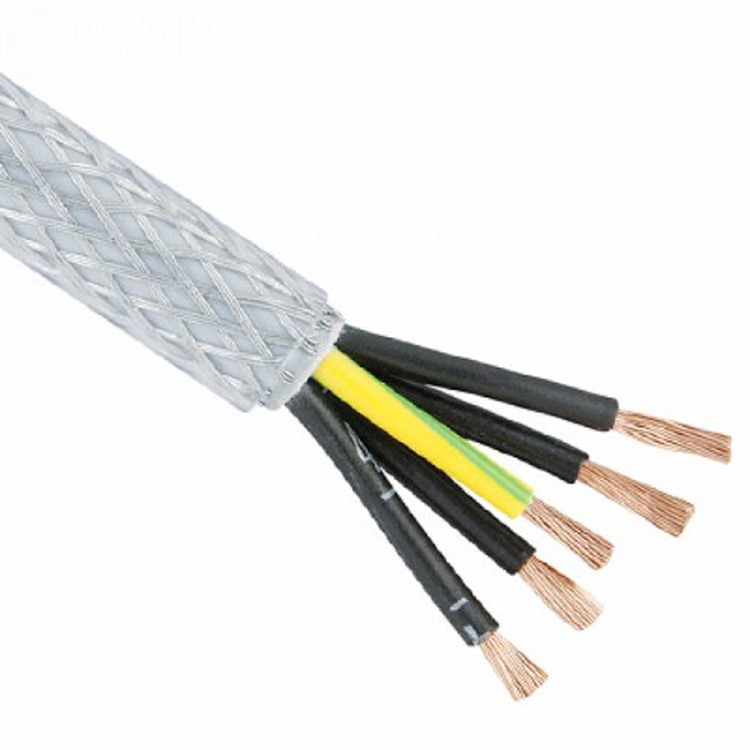

The steel braided flexible wires come in various configurations, including single-core and multi-core designs. Single-core cables have a single conductor within the braided steel sheath, while multi-core cables consist of multiple conductors individually insulated and then bundled together before being covered by the steel braiding.

These cables are often terminated with connectors or fittings that enable easy connection to electrical devices or power sources. The type of connectors used can vary depending on the specific application and industry requirements.

Steel braided flexible wires are known for their robustness, resistance to mechanical stress, and high flexibility, making them suitable for demanding environments. They are commonly used in applications such as power transmission, control systems, signal transmission, and as wiring harnesses in vehicles.

When working with steel braided flexible wires, it is important to handle them carefully and avoid damaging the outer steel braiding, as it can affect the cable’s overall performance and protection capabilities.