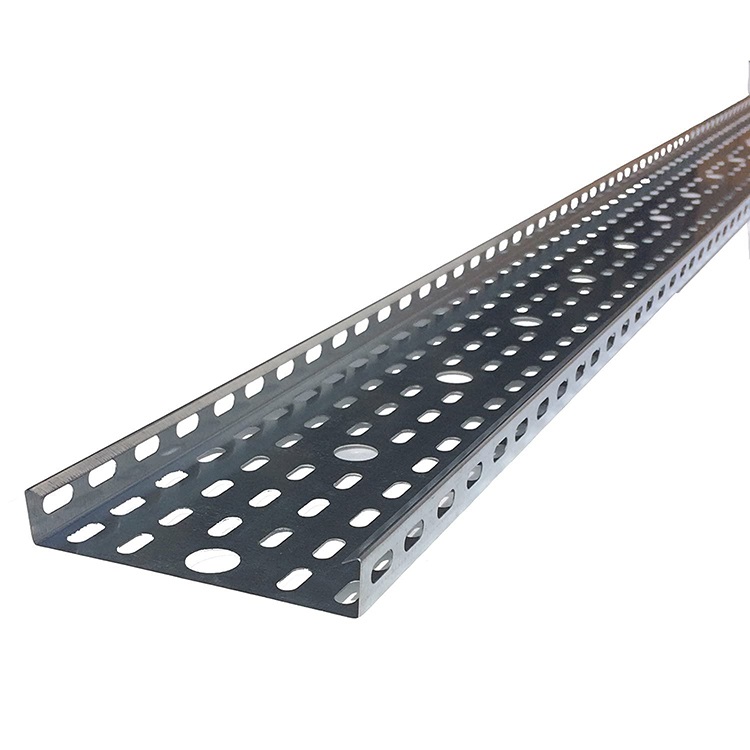

Hot Dipped Galvanized Perforated Cable Tray

Hot Dipped Galvanized Perforated Cable Tray

Hot-dipped galvanized perforated cable trays are a type of cable management system commonly used in industrial and commercial buildings to support and organize electrical and networking cables. The cable trays are made from steel sheets that have been perforated with small holes to allow for cable routing and ventilation.

The hot-dipped galvanization process involves immersing the steel trays in a bath of molten zinc, creating a protective coating that helps prevent corrosion and extends the lifespan of the cable tray. This makes them suitable for use in various environments, including outdoor and corrosive areas.

Perforated cable trays are designed with a pattern of evenly spaced holes along the length and width of the tray. These holes allow for easy installation of cables and provide ventilation to dissipate heat generated by the cables. The perforations also allow for visibility and accessibility, making it easier to inspect and maintain the cables.

Hot-dipped galvanized perforated cable trays come in various sizes and configurations to accommodate different cable capacities and installation requirements. They are typically available in straight sections, fittings, and accessories, allowing for customized installations based on the specific needs of the project.

Some advantages of hot-dipped galvanized perforated cable trays include:

- Corrosion resistance: The galvanized coating protects the trays from rust and corrosion, making them suitable for both indoor and outdoor applications.

- Strength and durability: The steel construction provides a sturdy and robust structure that can support heavy loads of cables over long spans.

- Ventilation and heat dissipation: The perforations allow for airflow, preventing the buildup of heat within the cable trays and minimizing the risk of overheating cables.

- Easy installation and customization: The perforations make it convenient to secure and route cables within the tray. The various sizes and accessories available enable customization to fit specific installation requirements.

- Accessibility and maintenance: The open design of perforated cable trays allows for easy access to cables for inspection, troubleshooting, and maintenance purposes.

Hot-dipped galvanized perforated cable trays are widely used in industrial plants, data centers, commercial buildings, and other locations where cable management and organization are essential. They offer a reliable solution for protecting and routing cables while ensuring efficient airflow and maintaining a neat and organized environment.