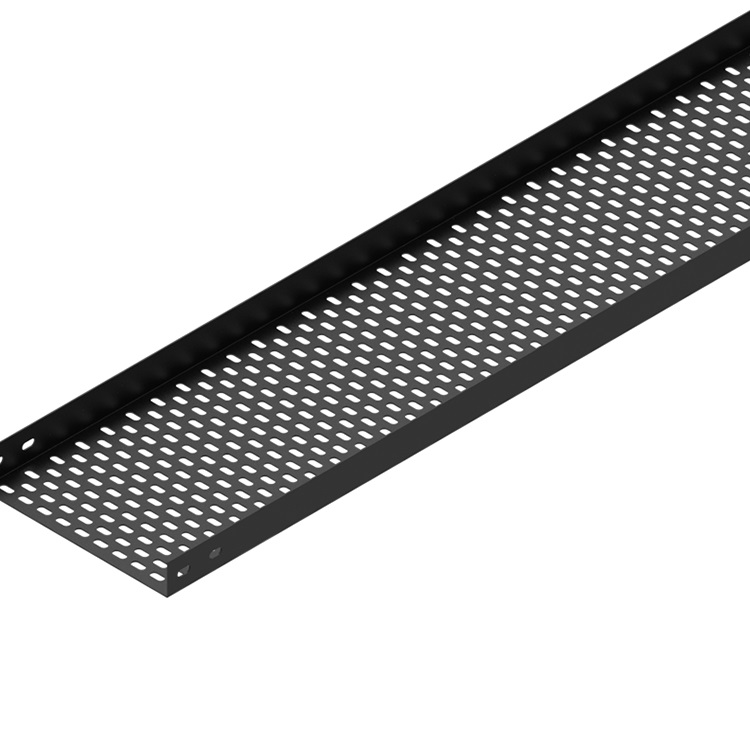

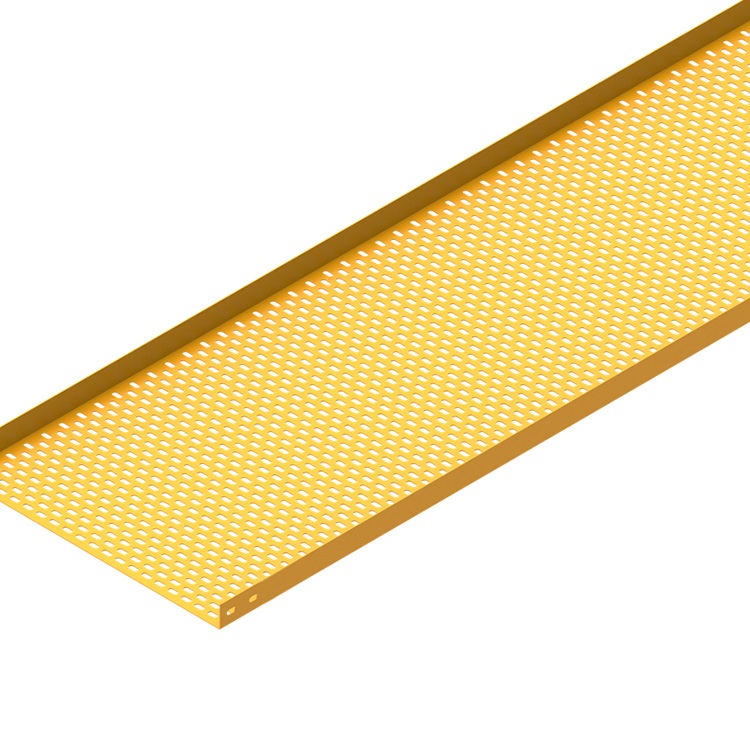

MS Powder Coated Perforated Cable Tray

MS Powder Coated Perforated Cable Tray

MS Powder Coated Perforated Cable Tray refers to a type of cable management system used in electrical installations. Let’s break down the term:

MS: MS stands for “Mild Steel,” which is a type of low-carbon steel that is commonly used in various applications due to its strength and affordability. In the context of cable trays, MS refers to the material used to construct the tray.

Powder Coated: Powder coating is a finishing process applied to metal surfaces to enhance their durability and appearance. In this case, the MS cable tray is coated with a layer of powdered paint that is electrostatically applied and then cured under heat to create a hard and smooth finish. Powder coating provides protection against corrosion and improves the tray’s resistance to wear and tear.

Perforated: Perforated cable trays have a series of regularly spaced holes or slots along their length and width. These perforations serve multiple purposes. They allow for better airflow around the cables, which helps dissipate heat generated by the electrical currents. Perforations also enable easy installation and removal of cables, as they provide access points for securing and organizing the wiring.

In summary, an MS Powder Coated Perforated Cable Tray is a cable management system made of mild steel, coated with a powder finish for added protection, and featuring regularly spaced holes or slots to facilitate cable installation, airflow, and maintenance. It is commonly used in electrical installations to organize and support cables, ensuring efficient and safe routing of power and communication wires.